Optimizing Performance: The Critical Role of Material Selection for Custom Rubber Components

In the precision manufacturing of custom rubber components, the choice of elastomer is paramount. It dictates the component’s performance, longevity, and ultimately, its suitability for a specific application. At Raj Industries, an ISO 9001 certified manufacturer established in 1994, we understand that an informed material selection is not merely a preference but a critical engineering decision that underpins product reliability.

Understanding Application Requirements for Elastomeric Components

The first step in specifying a custom rubber component involves a thorough analysis of its operational environment and functional demands. This systematic approach ensures that the chosen material possesses the necessary physical, mechanical, and chemical properties to withstand operational stresses without premature failure.

- Temperature Range: Components must maintain integrity across anticipated ambient and operational temperatures, from cryogenic to extreme heat.

- Chemical Compatibility: Exposure to oils, fuels, solvents, acids, bases, and process fluids necessitates elastomers with specific chemical resistance profiles.

- Mechanical Stresses: Considerations include tensile strength, tear resistance, abrasion resistance, compression set, and dynamic fatigue under cyclic loading.

- Environmental Exposure: Resistance to ozone, UV radiation, weathering, and water ingress are crucial for outdoor or harsh environments.

- Durometer (Hardness): Measured in Shore A or D, this property affects sealing effectiveness, vibration damping, and load-bearing capacity.

- Regulatory Compliance: Specific industries (e.g., medical, food & beverage) often require materials compliant with standards such as FDA, USP Class VI, or NSF.

Common Elastomers and Their Distinctive Properties

A diverse range of elastomers is available, each offering a unique combination of characteristics. Understanding these properties is fundamental to effective material specification:

- EPDM (Ethylene Propylene Diene Monomer): Known for excellent resistance to ozone, weathering, UV light, steam, and polar solvents. Ideal for outdoor applications and water sealing. Typical operating temperature range: -40 °C to +120 °C.

- NBR (Nitrile Butadiene Rubber): Offers good resistance to petroleum-based oils, fuels, water, and some hydraulic fluids. Widely used in automotive, oil & gas, and industrial applications. Operating temperature range: -30 °C to +100 °C.

- Viton (FKM – Fluoroelastomer): Provides superior resistance to high temperatures, aggressive chemicals, fuels, and ozone. Crucial for demanding sealing applications in aerospace and chemical processing. Operating temperature range: -25 °C to +205 °C, with intermittent peaks higher.

- Silicone (VMQ): Excellent high and low-temperature flexibility, good electrical insulation properties, and biocompatibility. Frequently used in medical, food-grade, and high-temperature sealing applications. Operating temperature range: -50 °C to +230 °C.

- NR (Natural Rubber): Exhibits high tensile strength, elasticity, and abrasion resistance. Suitable for dynamic applications requiring good resilience. Operating temperature range: -20 °C to +80 °C.

- SBR (Styrene Butadiene Rubber): Offers good abrasion resistance and aging stability when compounded properly. Often used as a cost-effective alternative to natural rubber in many general-purpose applications. Operating temperature range: -20 °C to +100 °C.

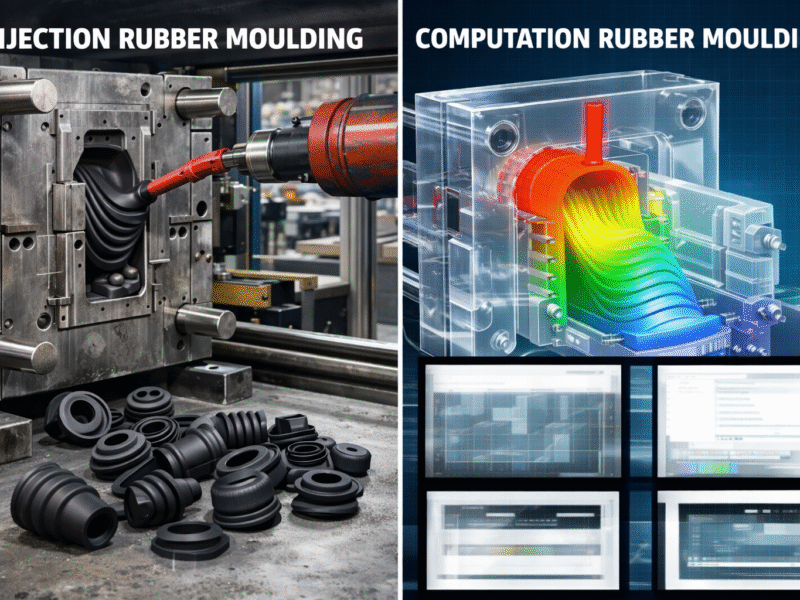

Precision Engineering and Managed Tooling

Beyond material selection, the manufacturing process significantly impacts component quality. Raj Industries utilizes advanced molding techniques, including compression molding, transfer molding, and injection molding, tailored to the specific material and component geometry. Our commitment to precision extends to our in-house tooling capabilities, which ensures rapid prototyping, consistent quality, and controlled manufacturing lead times for custom components.

Raj Industries: Your Partner in Material Specification

As an ISO 9001 certified manufacturer since 1994, Raj Industries provides comprehensive technical support and engineering expertise in material selection for custom rubber and plastic components. We collaborate closely with our clients to evaluate application parameters, recommend appropriate elastomers, and develop optimal manufacturing solutions. Our objective is to deliver components that meet stringent performance criteria and exceed expectations in diverse industrial applications across India and globally.